ROOT | GAGGENAU

2025 | Lund University | Master project | Collaborator Gaggenau

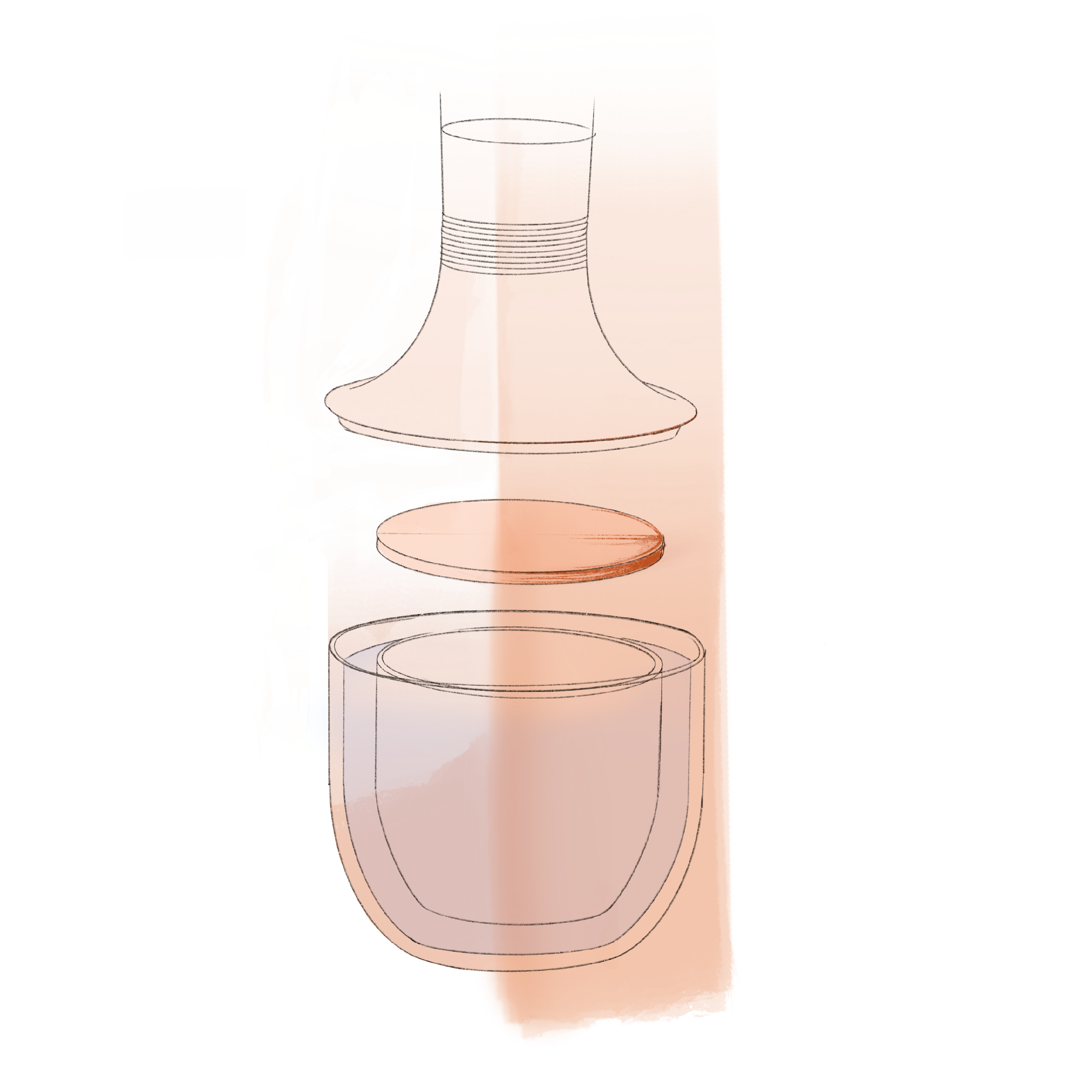

Root explores passive cooling in the deconstructed kitchen.

Using evaporation, the vessels create a climate aimed at keeping vegetables fresh for longer. It's a project where the raw qualities of earthenware are contrasted with Gaggenau’s more exclusive materials.

The brief from Gaggenau offered wide room for interpretation and revolved around four themes: luxury in extreme conditions, fire, hospitality, and manifesto.

Material: Earthenware | Manufactured in: Nittsjö, Sweden | Exhibited at: Milan Design Week & SSDD

-

Gaggenau | Dialogue with the Company

Gaggenau is built on a heritage of steel, performance, and uncompromising quality. From its industrial origins, the brand has evolved into a pioneer within the exclusive kitchen segment. With cutting-edge technology and carefully selected premium materials, Gaggenau creates appliances that seamlessly unite function and aesthetics – for the discerning customer who refuses to compromise on quality.

-

Zeer Pot | Function

The zeer pot, also known as a pot-in-pot cooler, is a form of passive refrigeration consisting of two ceramic vessels – a smaller one placed inside a larger, with damp sand in between. As the water in the sand evaporates, heat is drawn from the inner pot, lowering the temperature. The result is a simple yet effective cooling method, particularly useful for storing vegetables in hot climates. Traditional pots often appear raw and rustic in expression, while more recent reinterpretations tend to feel purely modern.

-

Markus West | Chef

“The question is: what is luxury? Who decides what counts as luxury? Is it the price, or is it something else that creates the feeling of luxury?”

For many, luxurious food is associated with high cost — an ingredient that is expensive but often requires very little preparation. Take Kalix Löjrom (Kalix vendace roe), for example: it’s luxurious and easy to serve. On the other hand, something inexpensive that demands a great deal of work may still not be perceived as luxury.

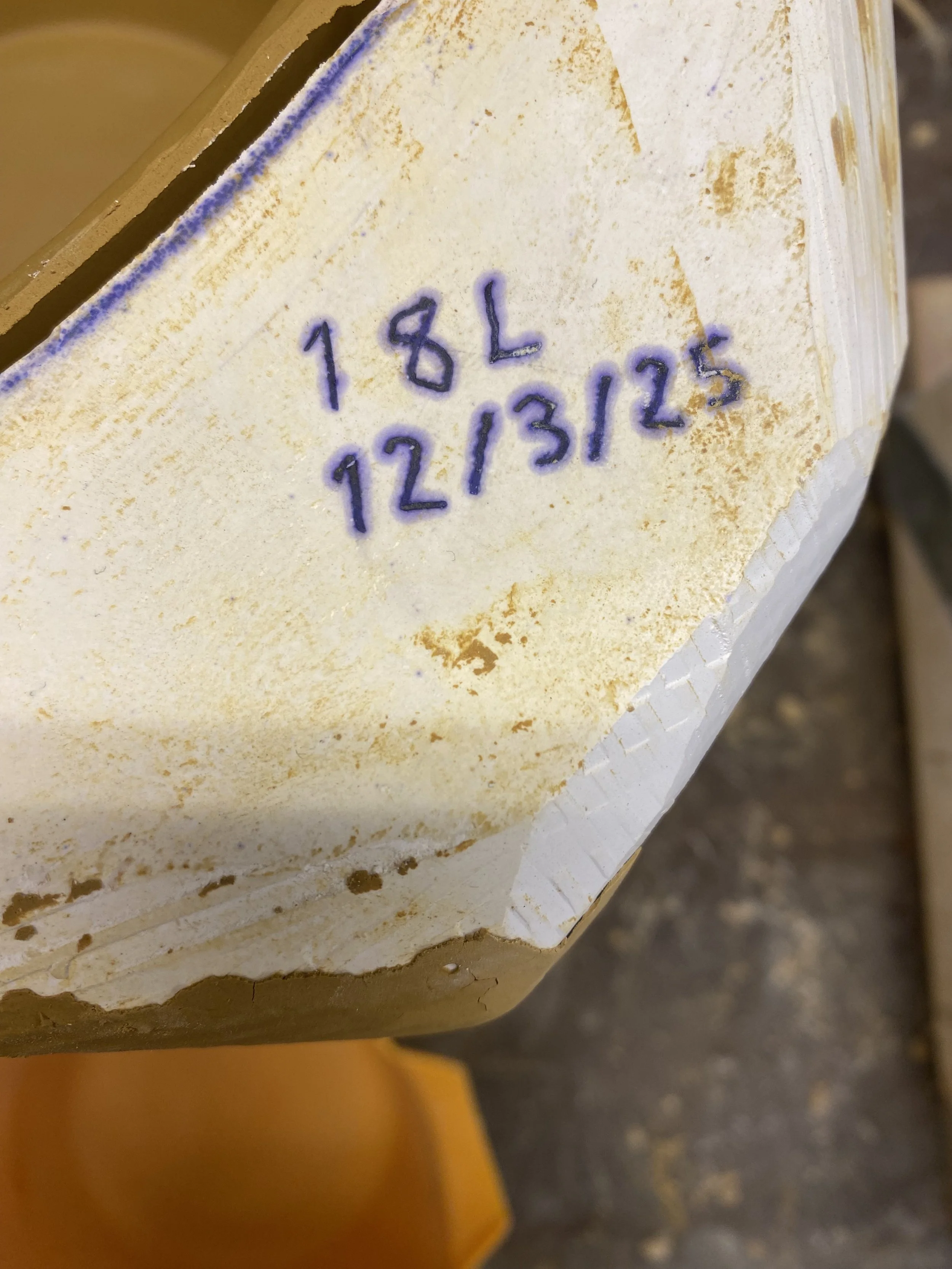

A project where form followed function, and where I deepened my understanding of clay as a material. Robert, who works with casting molds in Nittsjö, suggested adding a pattern to the lid to prevent the clay from warping or collapsing during drying. The result was a series of ridges that not only gave the pot its character but also offered a subtle guide to how it is meant to be used.

As for cooling performance, a test was carried out at a room temperature of 23 °C. After 24 hours, with damp sand between the pots, the inner temperature had dropped to 14 °C. A clear demonstration of how effective passive cooling can be – using nothing but clay, sand, and water.